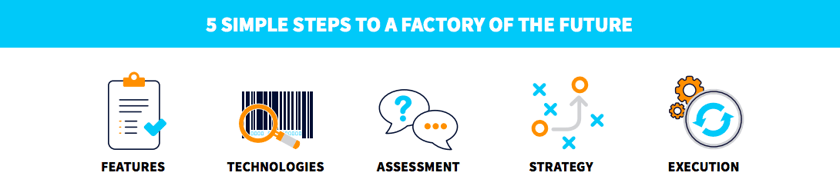

This playbook will guide you through your technology options as you modernize your factory and business operations

Growing manufacturers and those using entry-level accounting or legacy manufacturing ERP systems must modernize factory and business operations to remain competitive. To maintain their competitive edge, manufacturers may need to replace their business system or acquire bolt-on applications with limited integration and high installation, maintenance, and support costs. This playbook provides manufacturers with an overview of discrete manufacturing software / ERP features and advice for connecting ERP applications with innovative manufacturing technologies. In addition, it includes a self-assessment to determine what steps to take next with strategies to execute on technology implementations, setting a future-proof platform for growth.

In this playbook, you’ll learn:

- Which eight feature categories to look for in your next manufacturing ERP.

- How a modern ERP can support your use of 14 emerging technologies.

- Four simple steps to digital transformation.

- The four phases of creating a modern factory.

- Why Acumatica Manufacturing Edition is ideal for transforming your manufacturing business.

Acumatica provides the best business and industry management solution for transforming your business to thrive in the new digital economy. Built on a future-proof platform with an open architecture for modern technologies, rapid integrations, scalability, and ease of use, Acumatica delivers an unparalleled experience for users and customers alike

A modern factory is crucial for manufacturers to thrive in today’s digital economy. Unfortunately, entry-level business applications and legacy ERP software force many manufacturers to invest in costly customizations or complex, expensive, and disconnected hardware, systems, and processes.

Manufacturers need to understand how modern technologies can transform their businesses through automation to improve quality, increase throughput, bolster sales, cut costs, and increase profits.

A disciplined strategy is critical to the success of manufacturing digital transformation. The strategy establishes a solid foundation, provides research, and defines priorities for the modernization plan.

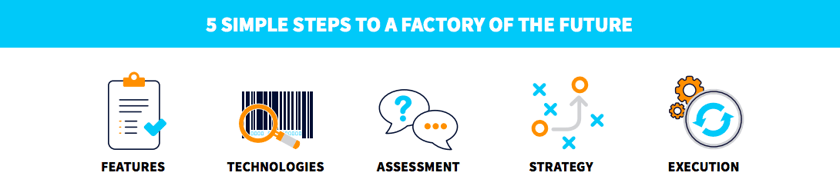

FEATURES

Introduction to Manufacturing ERP

There are eight feature categories manufacturers need to consider when modernizing their manufacturing operations and business systems. These are general features, accounting, order management, inventory management, product design, production management, planning and scheduling, and analytics and reporting. These feature sets are crucial to every factory modernization project. They provide manufacturers with the tools they need to eliminate manual data entry, streamline business processes, connect to modern manufacturing technologies, and improve visibility into all manufacturing business transactions.

TECHNOLOGIES

Manufacturing Technologies

There are a plethora of modern technologies transforming today’s manufacturing processes. Additive manufacturing with 3D printers, connected machine-to-machine (M2M) integrations, connected Industrial Internet of Things (IIoT) devices, wearable technologies, and other advancements are disrupting manufacturing operations. Be prepared with a future-proof ERP application designed for low-code or no-code integrations using Open APIs to streamline and automate operations.

ASSESSMENT

Your Digital Transformation Journey

Every manufacturer is different, and so too is their factory modernization journey. Companies on entry-level accounting systems have few tools to connect systems. Established manufacturers on legacy ERP systems also have difficulty connecting to today’s technologies. Your manufacturing needs vary depending on your industry, the types of products you make, and your customers. Complete the self-assessment survey to determine where you are today and what next steps you should take.

STRATEGY

Steps to Digital Transformation

It is challenging to modernize manufacturing operations without a comprehensive plan. You have technologies in place today but are they the right ones to take you to the next level? You have implemented features in your ERP system, but are they set up correctly, and are there other features you could use? Set a solid foundation by researching options, prioritizing activities, and developing a detailed plan.

EXECUTION

Creating a Modern Warehouse

It is time to execute the modernization project once you have defined your plan. Remember that you do not have to automate everything simultaneously. It is easier to start with simple technologies such as barcode scanning or connections to disparate quality, maintenance, or shop floor applications. Execution covers four phases: preparation, go-live, review, and continuous improvement. Each phase is essential for the successful roll-out of new warehouse strategies.

Aqurus Solutions

Aqurus Solutions