The ROI of ERP for Building Materials Manufacturing: Is It Worth It?

Is Investing in an ERP for Building Materials Manufacturing Worth the Cost? For building materials manufacturing software, efficiency is everything....

2 min read

Murray Quibell

Feb 27, 2025 10:54:04 AM

Murray Quibell

Feb 27, 2025 10:54:04 AM

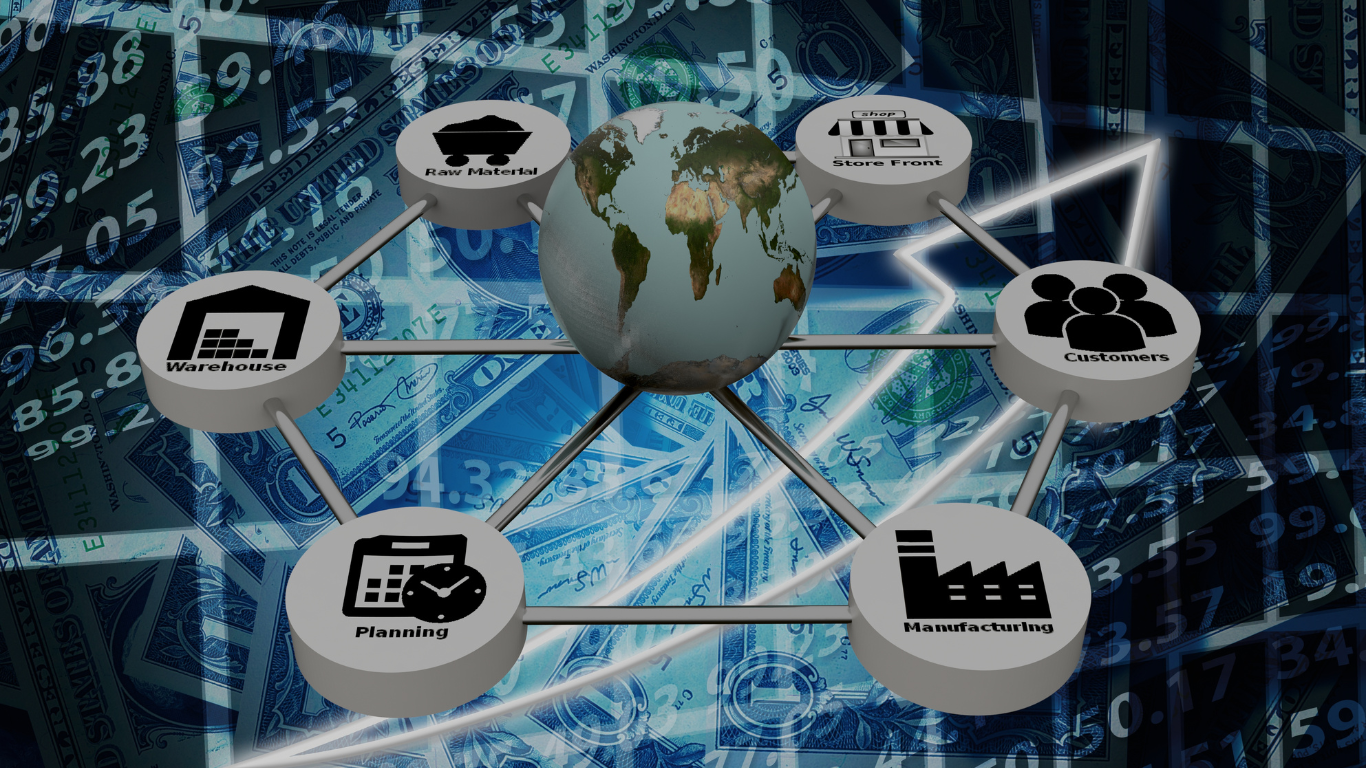

Since COVID, there's no doubt that the building materials manufacturing supply chain faces various challenges, from fluctuating raw material costs to unpredictable shipping delays. Events like global supply chain disruptions, natural disasters, and labour shortages can create bottlenecks, leading to missed deadlines and lost revenue. Manufacturers struggle with visibility, forecasting, and supplier management without the building materials manufacturing solutions.To stay competitive, manufacturers need a robust supply chain strategy that starts with a modern Enterprise Resource Planning (ERP) system.

A cloud-based ERP solution like Acumatica provides real-time visibility, automation, and control across the supply chain. Here’s how ERP helps building materials manufacturers stay agile and prepared for disruptions:

Managing inventory effectively is one of the biggest challenges for manufacturers. Too much stock ties up capital, while too little can halt production. ERP software provides real-time inventory tracking, helping businesses:

ERP systems integrate historical sales data with market trends, helping manufacturers predict demand more accurately. With data-driven forecasting, businesses can:

Manufacturers rely on multiple suppliers for raw materials like lumber, steel, and concrete. A disruption at any point in the supply chain can cause delays. ERP enhances supplier management by:

Unexpected supply chain issues can disrupt production schedules. With ERP, manufacturers can quickly adjust production plans by:

Late deliveries impact customer satisfaction and project timelines. ERP helps manufacturers improve logistics by:

Take your building materials manufacturing strategy to the next level with our hands-on Acumatica resources. From in-depth software demos to downloadable guides, you’ll gain valuable insights into how Acumatica can support building materials manufacturing operations. Explore how this mobile-friendly platform streamlines workflows, enhances efficiency and adapts to your unique business needs. Visit our Acumatica Resources today and see how Acumatica can transform your approach to building materials manufacturing.

Traditional, on-premise ERP systems limit flexibility. Cloud-based ERP solutions offer additional benefits that enhance supply chain resilience:

At Aqurus Solutions, we help building materials manufacturers implement Acumatica Cloud ERP to streamline supply chain operations and improve resilience. Our tailored ERP solutions give you the tools needed to reduce risks, improve efficiency, and stay ahead of market fluctuations.

Want to learn more? Contact us today for a free consultation and discover how Acumatica ERP can transform your supply chain management.

Is Investing in an ERP for Building Materials Manufacturing Worth the Cost? For building materials manufacturing software, efficiency is everything....

Integrated Cloud ERP with EDI Innovation isn't just a buzzword in eCommerce and manufacturing—it's the key to staying ahead of the curve. One of the...

ERP Software for Distribution and Manufacturing Compliance in Canada Managing a distribution or manufacturing business in Canada can be challenging,...